1

/

of

4

Pettit Racing Protek-R Rotary and Piston Engine Fuel Lubricant

Pettit Racing Protek-R Rotary and Piston Engine Fuel Lubricant

Couldn't load pickup availability

If we expect our rotary engines to deliver top performance year after year, it is clearly evident that extra lubricant must be added to the fuel.

Protek-R fuel lubricant was developed by Pettit Racing as a fuel premix for rotary engines. Protek-R is added to the fuel tank and injected with the fuel to all critical surfaces in the engine. Benefits include reduced friction and heat, which leads to less wear, as well as protection from rust and corrosion. Especially with today's fuels that are blended with ethanol. Ethanol is basically alcohol, great for cleaning, but with rotary engines this can wash away the minute oil film injected by the OEM oil metering pump, this leaves critical surfaces void of lubricant and unprotected. Regular use is proven to deliver performance and longevity beyond expectation.

Adding Protek-R to your fuel has many benefits, the following are just a few:

- It keeps your fuel pump happy, less friction, cooler running, longer life.

- It helps prevent water absorbed by ethanol from rusting the metal parts of the fuel system.

- Injectors get lubricated resulting in less friction, less wear, and more consistent fuel delivery.

- Increased MPG on rotary and piston engines.

- Better sealing of all internal seals resulting in a slight bump of effective compression.

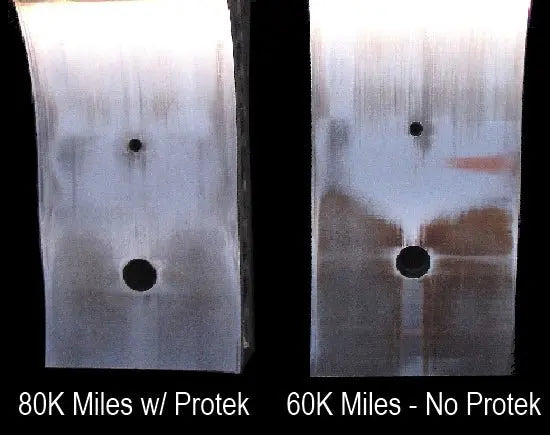

The OEM oil metering system is responsible for lubricating the delicate apex seals, compression seals, and housing surfaces that are common to every rotary engine. Oil is fed from the engine oil pan to a variable ratio metering pump. Then it’s injected into the engine where it partially blends with the onrushing air-fuel charge. This incomplete blending and high fuel-to-oil ratios of 400:1 and higher are cause for alarm. Also, unleaded fuels typically have additives designed to clean piston engines, then high combustion temperatures of the rotary together with ethanol blended fuels cause the minute film to disperse and/or vaporize leaving all your critical surfaces clean and dry without protection. This causes increased friction and wear resulting in decreased performance and longevity. With over 30 years experience and more than 2000 rotary engines built, we know excessive wear on apex and compression seals as well as critical housing surfaces is caused from inadequate lubrication. Without extra lubrication being added in the fuel, friction and heat will cause accelerated

wear and likely result in premature failure of your engine.

wear and likely result in premature failure of your engine.

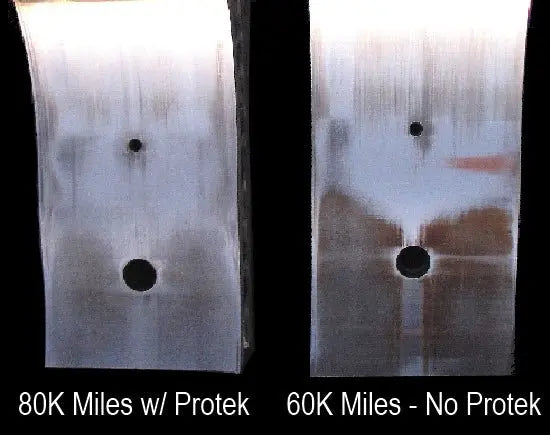

Protek-R is proven over & over to reduce friction, heat and wear extending rotary engine life by 30% to 60% or more depending on consistency of use and your driving habits.

Protek-R blends completely with your fuel lubricating all the critical internal surfaces. This provides reduced friction and wear, adding longevity and keeping the power levels up. Just what the rotary needs to last strong!

In just one 24 hour race a Pettit race engine will get a lifetime of use and punishment, but since we mix Protek-R in the fuel they have little wear when compared to the average street engines we regularly disassemble. This is especially evident on turbocharged or high RPM rotaries like the Renesis.

Pettit Built engines are the only turbocharged rotary engines in racing history to finish the grueling Rolex 24 at Daytona. Could Protek-R be a factor? We think so!

Here at Pettit Racing we know how fun and important it is to have a good running rotary engine and keep it running for many miles and years, that is why Protek-R was developed in the first place. For RX-8 owners, some Renesis engines have weak or low compression. Mazda says “heat generated friction” is the cause, but since factory recalibration for the RX-8 ECU increases injected oil for the high revving Renesis, could they just need some Protek-R to help cut friction and reduce wear? We think so.

Recommended Premix Ratios

- For street use and spirited driving add Protek-R at a ratio of a little less than 100:1, or approx 1 gal fuel with 1 oz of Protek-R.

- For track racing, deleted OEM oil metering pumps or high boost applications add Protek-R at a ratio of 60:1, or 1 gal fuel with 2.1 oz. of Protek-R.

- For hwy & cruising the minimum recommendation is 200:1 or approx 1 gal fuel with .5 oz of Protek-R.

- For piston engines, add Protek-R at 300:1 or about .4 oz per gallon

Within 15-20 minutes of adding Protek in the gasoline of piston engine vehicles there is typically a 1-3 MPG gain. Nearly everyone after the first use comments, “Its the best MPG ever displayed and my vehicle feels smoother and seems to run better!" Some folks disagree, but think about this, diesel piston engines can make it to a million miles, but gasoline piston engines never even get close. Both use nearly the same parts and materials but diesels have higher compression, more stress and higher loads. So why is it they last the longer? Diesel fuel is oil! There is no doubt using fuel lube in gas piston engines will more than double their longevity.

Share